Designer Notebook: Inside The Development Of The New EAW KF740 Line Array

The goals and metholodogy behind a new line array.

Scale & Packaging

It was also very important to us that the KF740 be as lightweight and efficient as possible.

It was also very important to us that the KF740 be as lightweight and efficient as possible.

Especially at the present time, given the state of the economy, minor considerations such as cartage have become especially big factors in the purchasing process for sound companies.

Extensive 3-D modeling was deployed to develop a rugged yet lightweight exterior-grade Baltic birch plywood enclosure, protected by wear-resistant textured coating and powder-coated steel grille.

In combination with the neodymium transducers, each module checks in at just over 100 pounds.

Its profile is identical to that of the KF730 in terms of height and depth (13 inches by 17.5 inches), while the KF740 is about 40 percent wider at 40.1 inches.

These compact enclosures require a minimum of truck space, and caster pallets for easy transport are available.

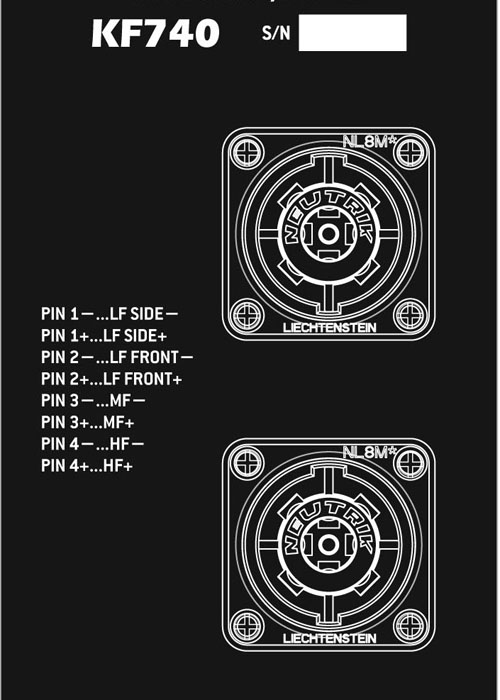

The dual Neutrik Speakon STX Series NL8 connectors on the rear panel provide access to each of these sections separately. The low frequency sections; side and front, are wired separately but can be driven by the same DSP channel.

The integral rigging system is constructed of structural high-strength aluminum to meet the weight goals, strong enough to hang a 16-module array at a 10:1 design factor.

After completing the design using a solid modeling program, we utilized Finite Element Analysis software to conduct virtual pull tests that provided invaluable information in furthering the integrity of the rigging, followed by actual physical failure testing.

We also advise that all arrays be structurally verified with EAW Resolution software, which calculates (in real time) the stress load on all rigging points of every enclosure. This is critical because every array is different.

Users can quickly and easily construct vertical arrays ranging from 4 to 16 enclosures. In most cases, choosing the correct points on the multi-position fly bar will aim the array, although some angled configurations will require pull back using an inverted fly bar. Boxes are quickly secured with precision quick-release rigging pins.

The rigging system permits box-to-box angles of 12, 9, 6, 3, and 1.5 degrees, while always keeping module faces contiguous. Under normal conditions, easily hung arrays can cover listening areas ranging from approximately +10 degrees to -70 degrees along the vertical axis.

The rigging also accommodates “radical” array configurations that can cover any vertical angle. Accessory adapter bars for easy configuration within KF730 and KF760 arrays are also available.

Inherent within all of our goals was one consistent theme: to maintain and further the EAW heritage of consistent pattern control while attaining output levels comparable to larger systems.

Preliminary customer response indicates that with the new KF740, we’re on the right track.

Nathan Butler serves as principal design engineer at EAW.